- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- שפה עברית

- беларускі

- Bosanski

- ქართული

- O'zbek

Selection Analysis of Fuses for Photovoltaic Array Protection in Solar Photovoltaic Power Generation System

2024-12-13

Photovoltaic power generation system (abbreviated as PV) consists of components and subsystems that can directly convert incident light energy into electrical energy, of which the photovoltaic array is the core unit. The photovoltaic array directly converts the incident solar radiation into DC power by connecting the solar panels to the photovoltaic array connection box, and then converges it to the inverter or directly applies it through the connection box. As the part of the system that accounts for up to 70% of the cost, the protection of the photovoltaic array and the optimization of power generation efficiency have become key areas of technological development.

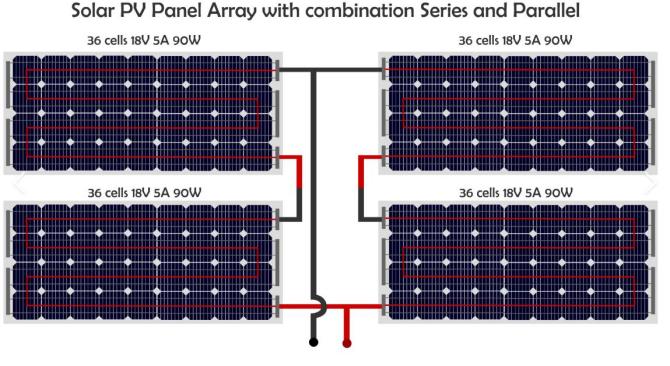

In order to improve the efficiency of the photovoltaic system, multiple photovoltaic panels are connected in series to form a photovoltaic string, and multiple groups of photovoltaic strings are connected in parallel to form a photovoltaic array. The current of the photovoltaic array is converged through the connection box and enters the downstream application link. In order to prevent the photovoltaic panel from becoming an energy load and affecting the overall power generation efficiency when a fault occurs, and to prevent overcurrent hazards caused by miswiring or local abnormalities, each photovoltaic string needs to be installed with fuses at both ends. When a short circuit fault occurs in the photovoltaic string, the series fuse will quickly blow and isolate the faulty part to ensure the normal operation of the array as a whole.

In addition, array fuses can also provide protection against currents fed back from downstream components, especially when the short-circuit current is higher than the current of a single PV string. The rated breaking capacity of the fuse must be able to cover such extreme conditions to protect the safe operation of the system.

International standards and domestic specifications

In terms of protection of the PV DC side, relevant international and domestic standards provide important guidance. For example, Article 690.99 of the US National Standard NASI/NFPA 70 "National Electrical Code" (NEC) clearly states that conductors and equipment in PV subsystem circuits, PV output circuits, inverter output circuits, and energy storage battery circuits must meet the requirements of conductor and equipment protection clauses. In addition, China adopts the equivalent IEC standard GB/T 16895.32-2021, which stipulates that under standard test conditions, when the continuous current carrying capacity of the cable is equal to or greater than 1.25 times the short-circuit current, overload protection can be ignored, but it is also recommended to select fuses in combination with the manufacturer's specific product instructions.

IEC has developed the IEC 60269-6 standard specifically for photovoltaic system protection fuses, which clearly stipulates the performance requirements of photovoltaic fuses, such as being able to withstand continuous short-circuit currents and quickly blow. At the same time, UL's technical specification Subject 2529 provides important guidance for low-voltage fuses in photovoltaic systems. The two are slightly different in the calculation of the blowing current and the use of temperature correction coefficients.

Fuse selection considerations

When selecting fuses in photovoltaic systems, the following indicators should be focused on:

Rated voltage: The rated voltage of the fuse must meet the maximum open-circuit voltage (Voc) that the system may reach. Especially in cold areas, the open-circuit voltage correction value of the photovoltaic panel at the lowest ambient temperature should be considered.

Rated current: For fuses connected in series with photovoltaic panels, the rated current In≥1.56 Isc (Isc is the short-circuit current) is usually required. The IEC standard is revised to In≥1.42 Isc, and the US UL standard is In≥1.35 Isc. It needs to be selected in combination with the actual application environment.

Breaking capacity: The breaking capacity of the fuse should be sufficient to cope with the short-circuit current peak and protect the equipment from damage.

Environmental adaptability: In the case of high temperature or dense installation, the rated value should be appropriately reduced according to the recommendations of the fuse manufacturer to ensure long-term stable operation.

Conclusion

The installation of DC fuses in photovoltaic arrays is not only a necessary means to protect equipment and improve power generation efficiency, but also an important measure to ensure the safe operation of the entire system. Reasonable selection of fuses requires comprehensive consideration of factors such as the working environment of photovoltaic panels, short-circuit current, open-circuit voltage, etc. to ensure the long-term reliability and economy of the system.

For example, Zhejiang Galaxy Fuse Co., Ltd's 1000VDC 30A 10x38mm Solar Py Fuse Link and 1500VDC 30A 10x85mm Solar PV Fuse Link and 1500VDC 630A 3L Bolt type Solar PV Fuse Link photovoltaic fuses have been widely used in key protection positions of photovoltaic connection cabinets. With excellent performance and high-standard certification, these fuses provide stable and reliable solutions for photovoltaic power generation projects, helping the system to operate efficiently.